The French word "papier-mâché" literally translates as "chewed paper," however, the papier-mâché used for a Russian lacquer box is produced in a much more complicated process. Despite their delicacy and seeming fragility, papier-mâché products are very durable and functional. In fact, papier-mâché, as it is produced for a true Russian lacquer miniature, is more stable than wood as it has no grain and will not warp or crack. An authentic Russian lacquer box produced using traditional techniques and materials can travel anywhere in the world and it will not be affected by the climate.

Boxes and other objects are made of cardboard sheets, pressed and formed, then boiled in linseed oil. This papier-mâché is then baked in an oven. At this point the material can be worked like wood. Trained joiners assemble the boxes, applying hinges and two coats of primer-paint. The blank is then oven dried and given to the artist to begin the painting. Extremely fine brushes are used to achieve the fine lines and details in each painting. Artists prefer to make their own brushes and mix their own pigments. A quality lacquer miniature may take several months to complete.

The same techniques and materials are used in and until it comes time to do the painting. The following photos and text below are taken from the book "Masters of Fedoskino" by Nadezhda Krestovskaya

The base of papier-mâché is pure wood pulp cardboard manufactured in strict compliance with the original formula.

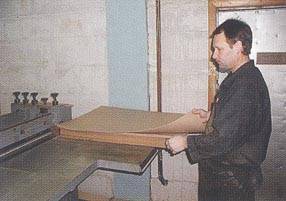

The cardboard is cut in strips according to the measurements of the shape and form of the future product.

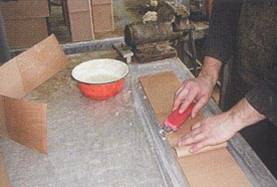

Paste is spread on the strips of cardboard.

The strips of cardboard are wound around special forms. The forms are put under pressure for an extended period of time.

The pressed cardboard, which has taken the shape of the form, is dried under specific conditions for twenty to thirty days. The roll, which becomes the body of the future article, is complete. The plates are pasted to make the bottoms and lids.

When the rolls and the plates have dried, they are soaked in a special bath of hot linseed oil.

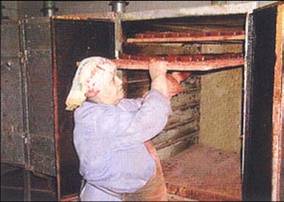

Then, they are dried in ovens at a high temperature.

The rolls and the plates are cut to make a semifinished product.

The nature of this light and durable material allows the craftsmen to smooth the product with a special sanding machine.

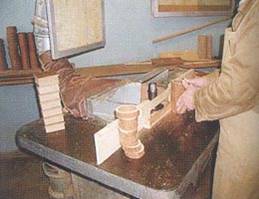

The lids and the bottoms are glued in place. The semifinished product is shaped into the desired form.

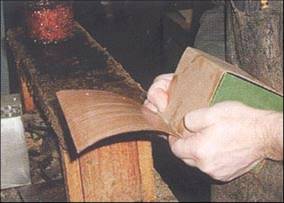

The product is sanded smooth.

Handmade custom brass hinges attach the lid to the body of the box.

The product is puttied to fill imperfections...

... and coated with several layers of primer.

Each layer is dried in special cabinets.

The product is hand polished to obtain an absolutely smooth surface.

The outside of the product is painted with several coats of black lacquer.

The inside of the article is painted with several coats of red lacquer.

Each layer is dried. Altogether, no less than thirty layers of lacquer and paint are applied to each product. The entire process, from cutting the cardboard to the final polishing, requires four to six months.

At this stage, the miniaturists begin their creative work. The lacquer painting is done with oil paints (egg tempera in Palekh, Mstera, and Kholui), utilizing a three-dimensional layered process. This technique is peculiar to the Fedoskino craft.

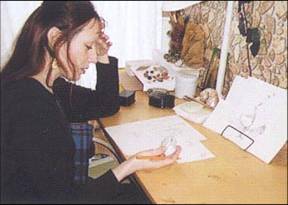

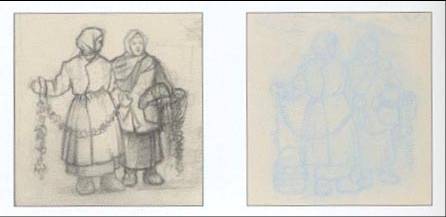

Numerous sketches and studies are required. First a drawing is made on paper, then copied on to tracing paper.

Next, the drawing is transferred from the tracing paper to the lid of the box using chalk to create an outline of the basic composition.

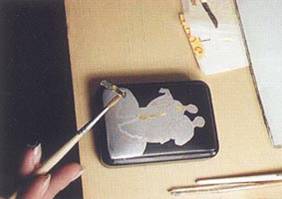

A metallic ground such as aluminum powder or gold leaf is applied. In some cases mother-of-pearl may be inlaid.

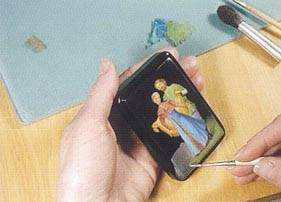

The basic colors are applied in the first layer of the painting.

The painting is covered with several layers of lacquer and allowed to dry after each application.

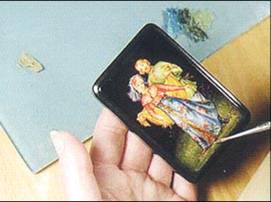

The artist proceeds to apply the second layer of the painting in a more defined manner and all details are given careful attention. Each layer is given a coat of lacquer and dried.

The third and final layer is applied to highlight certain areas and to deepen shades.

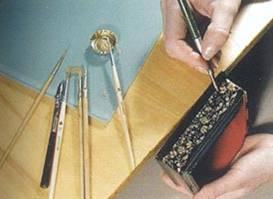

The ornamentation of the body consists of a gold border applied around the lid or sides. This ornament is hand painted.

A lacquer miniature can also be decorated with tiny scales of metal foil or gold leaf inlaid. This decorative technique is called "skan."

Another widely used type of ornament is a grid imitating Scotch cloth. Ornamental lines of different colors are applied to the product using a drawing pen and a ruler.

When the painting of a product is completed and the paint is dry, it is given several coats of transparent lacquer

Each coat of lacquer is dried in an oven with high temperature.

The final step in the lacquer miniature process is the polishing.

The final hand polishing of a product achieves a mirror-like luster.